News

18 December 2024

The calculation whiz behind geotechnical analyses at the De Nieuwe Meer junction

Interview with Geotechnical Designer Justus Lagendijk

In the reconstruction of the De Nieuwe Meer junction, a crucial traffic hub near Amsterdam, Joosten Concepts is working closely with Geologics. Justus Lagendijk, a geotechnical designer at Geologics, shares insights about the collaboration and his work on this unique project.

The reconstruction of the De Nieuwe Meer interchange, one of the Zuidasdok projects, is of great importance for improving traffic flow in Amsterdam and the northern Randstad. This applies to both car traffic and public transport. To address the increasing traffic pressure, the A10 is being widened from four to six lanes. The contract for this large-scale renewal was won by Triax, a consortium of Besix, Dura Vermeer, and Heijmans.

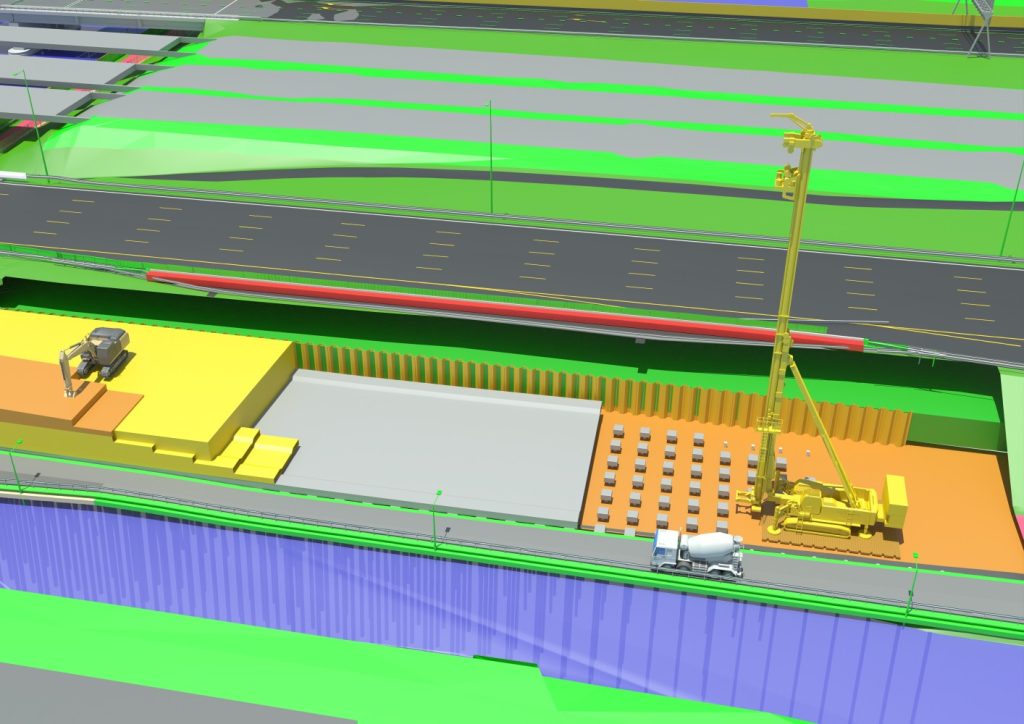

Part of this project involves the use of a pile mattress construction combined with a reinforced soil structure. Joosten Concepts, together with construction company Bonneveld, submitted a tender for the realization of this specific component of the major project—and succeeded. Currently, Justus is working hard on the final design.

Aerial photo of the current situation at the De Nieuwe Meer interchange

The power of collaboration

Joosten Concepts focuses on designing, supplying, and installing of constructions and systems. “To achieve this, they collaborate with various manufacturers, engineers, and contractors, including Geologics,” explains Justus. “Joosten Concepts actively searches the market for suitable tenders and then approaches us to create a preliminary design (VO). We take this on by performing calculations based on the provided specifications. From these, the types of geosynthetics are determined. All this data is combined into a cost estimate, with which Joosten Concepts successfully submitted their tender. Bonneveld handles the execution. The great advantage of this collaboration is that the construction consortium is fully relieved of this burden.”

Working on Location

A unique aspect of this project is that Justus temporarily works from the construction site office just a stone’s throw from the interchange. You can see the site clearly from the window. “I’ve become a regular at the Triax site office,” Justus says with a smile. “Being close to the project is important because the design is constantly changing. This way, we can quickly respond to changes and ensure everything fits together seamlessly.”

On the busiest days, about 100 to 150 people work here. Everyone has their own discipline and workspace. The short lines of communication between different parties ensure efficiency. The complexity of the project requires constant coordination. “The most interesting part is that I make calculations but rely heavily on input from others and vice versa. When parts of the design change, my calculations must also be adjusted. It is therefore essential to maintain continuous consultation,” Justus adds.

A Unique Combination of Techniques

The strength of this project lies in the unique combination of techniques, Justus explains: “We are building a pile mattress topped with a vertical reinforced soil structure. That’s quite rare.” A pile mattress consists of piles driven into the ground. Over the piles, we apply geosynthetic reinforcement that creates a spanning structure. On top of this comes a mixed granular material, wrapped in the same geosynthetic. Once folded, this geosynthetic forms a mattress. Through arch action, the mattress evenly distributes forces over the piles. This means no preloading time is needed and relatively little space is required.

The integrated approach of this project has resulted in a combination of these two different construction techniques. “This is necessary because the buildings are located so close to the road that there is no room for a traditional slope. We really need to build vertically, which works perfectly with a reinforced soil structure,” concludes Justus.

Impression of the construction of the pile mattress construction and reinforced soil structure

From design to realization

With the design phase nearly complete, the team is now focusing on execution. In 2025, construction will begin on the first reinforced soil structure. Justus looks ahead with enthusiasm: “The best part will be seeing how our calculations come to life. When you stand next to a structure that’s seven meters high, you truly grasp the scale of your work.”

The reconstruction promises not only improved traffic flow. Through traffic will soon be able to pass without obstacles, while destination traffic to the Zuidas will have a separate route. This will significantly reduce traffic jams. For Justus, the calculations are almost done, but once construction starts, he will certainly be returning regularly to closely monitor progress.

Meer nieuws

13 November 2025

Joosten is participating in the 2026 World Cup

Joosten has landed a special assignment: we are going to provide the perfect pitches for the 2026 Fo

12 November 2025

Rethinking the Shoreliner

For his graduation research at Wageningen University & Research, student Mike Cleintuar followed the

8 October 2025

JustNimbus: finalist for the Cobouw Innovation Award

Every year, the Cobouw Awards are presented. Their purpose is to reward inspiring frontrunners and s